January - December 2006

The weeks into January 2006 have seen some progress with the

much-needed strut cups finally procured via the great auction house of

the internet. My long-distance welder (in Anglesey) confirms having

received them and has started to repair the old struts. Meanwhile the

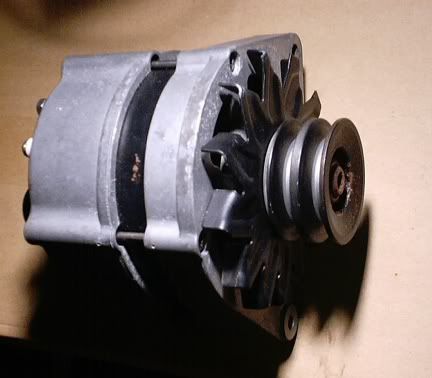

car has received a new (or refurbished) alternator from the same said

auction house and this seems to work fine.

A trip to Halfords has allowed me to get some paint (aerosol and

touch-in) for Bess's superficial defects here and there. All they

needed was Bess's paint code (219-5) to be read from the panel above

the radiator and the resulting colour is an exact match. A sort through

the attic has come up with a front valance repair panel and repair

panels for each sill. Could be handy when we reach that far-off goal of

sending Bess to the local welder for much needed major works. Other

minor trimmy bits needed for the front have been obtained and the

hot air duct connecting the exhaust manifold with the air filter has

been replaced with extentable aluminium tube - not very satisfactory

but hopefully will work for a while.

Finally in early February, the repaired struts arrive and

are reassembled with the new shock absorber inserts. The top strut nut

is tightened with the aid of a large vice and a wooden lever held in

place by clamps. So far so good. The struts themselves are then

re-attached to their springs with the help of a coil spring compressor

or two and, after a fair amount of fiddling about, they are ready to go

back on the car. In reality they were fitted, removed and reassembled a

few times to line everything up.

The weeks into Feb 06 have seen the struts refitted to the

car and the radius arm bushes fitted as per photo below. The tie rods,

radius arms etc have been bolted up loosely so that they can be

tightened when the wheels are back on the ground. Unfortunately one of

the brake back plate bolts sheared off in its hole which will

necessitate drilling it out and re-tapping the thread. Needless to say

things are going roughly in the right direction e.g. just beginning to

fit the callipers and wheel hubs back.

The broken bolt has been drilled out and replaced with a

smaller one - alas could not re-tap the hole with my tap-and-die set.

The callipers and disks are going back together more-or-less as they

should.

March has seen the front suspension reassembled fully and torqued up as required. The tracking has been set (see below) and now we are ready to move on to the next phase - sorting minor electricals for MOT and/or major welding.

The weeks into April 06 have seen Bess's electrics sorted

- all exterior, dashboard and console light are working. A major

clear-out of rubbish and re-wire to the radio aerial. A better steering

wheel has been fitted (no horrible smooth patches) and a few runs

up-and-down the yard have shown that all is reasonably well with the

steering and suspension. Alas the brakes will need more attention - the

wheels refuse to lock up on full braking.

Bess's jaw drops with laughter as she gets a new pair of

mincers. The pictures above and below show efforts to replace Bess's

headlamps and wipers with new units (from the great auction house of

the internet). Everything under the front bumper looks remarkably

rust-free and the headlamp washers and wipers all work. Blowing my own

trumpet again is sure to guarantee another major hitch.

The rear bumper has been removed to inspect for rust and one

rusted-through spot revealed itself (see below) - this will need

welding later on. Removing the bumper bolts was no mean feat with one

bolt breaking, another being bent and the threads on all were badly

jammed up. Anyhow a new set of bolts has been obtained and the bumper

and exhaust refitted. The headlamps and have been aligned and the wheel

trims refitted. Its almost MOT time but a couple of worries crop up

including the appearance of a thin blancmange inside the oil filler

cap. I will make do without a steering lock and will probably chance it

with the brakes in the MOT test, following advice from the

volvo300mania forum.

The next couple of months (May-June 2006) were taken up with sorting

electrical problems on another of my wrecks but the later weeks of July

have seen some progress with Blue Bess. Most importantly the car was

producing a strong smell of petrol whenever the engine had been run and

I eventually found this to be due to fuel leaking from the from

nearside box section which the petrol pipes run through. With help from

the volvo300mania forum, the problem was traced to perished flexible

hoses above and beside the petrol tank which were replaced by removing

the heat shield under the car and lowering the petrol tank. The problem

seems to 100% cured (in my unbiased view), the engine seems to be

running well and a nearly new front grille has been fitted with proper

clips! The only niggling worry is a strange shrieking sound from

the top end which comes and goes, but its usually soon after startup,

if at all.

Its Friday 18th August and Blue Bess is booked in for a mid-morning MOT test - I need to find out exactly what's wrong with her from the professionals. I get to the car a bit early and feel nervous at the prospect of crossing one of life's great thresholds. The journey to the test centre is fraught with brakes that hardly seem to work, steering that creaks, groans and hurls me towards parked cars at every turn not to mention the smoke issuing prominently from the exhaust. On arrival at the test centre I am told-off for driving in through the front entrance (I thought that was what front entrances were for) and leave the car for an hour to catch up with my sleep in the local cafe. On returning I see Bess on the ramp and after some time, the MOT tester returns to the reception and says to his colleague 'That 'as 'ad may-jor work! Everyfing on its noo. F***ing crazy!' and a few minutes later, to my horror, they they tell me its passed. £44 later I have no complaints. Now all it needs is new sills, front and rear valance, full welding to underside, painting and undersealing. Back at the garage, the next hour or two are spent starting to remove the front wings for the welder and getting over mixed feelings of jubilation and guilt that my paint-over-rust strategy has duped a poor boy into certifying this heap road-legal.

The work to remove the front wings continues over the next couple of days and a peep behind them reveals a fair amount of rust in the wheel arch which will have to be replaced.

August bank holiday weekend 2006 and the front wings have

been removed and bolted back on loosely for ease of removal by the

welder. The worry about creaks and groans from the steering led me to

suspect that I had previously fitted the strut-top thrust bearings

upside down! Finding one of the old ones in the garage left me in a

cold sweat, convinced that I really had fitted them wrongly. Hence I

decided to do the only thing that could be done...to remove one of the

struts and check. The next couple of hours were spent removing one of

the struts from a car that had just passed its MOT with flying colours.

Dismantling the same said strut confirmed that all was well after all.

The next couple days were then spent putting it all back together

again, setting the nuts and bolts to the correct torque and checking

the wheel alignment. No photos of this episode - its one that I would

rather forget. The rest of the long weekend was spent fitting the front

bumper back, removing odd bits and pieces and clearing the car out for

the welder. Things are happening fast (if that's possible with volvo

300's) - the car has insurance and its going to the welder for a quick

look over soon and he might be able to work on it in the first week of

September.

The weekend of 10 Sept 06 has seen the car returned from

the welder with copious amounts of underseal applied to the repaired

sections (as the pictures above and below will show). The poor man had

to spend 32 hours on the job but the price was about what I hoped it

would be - it could have been a lot worse. He seems to have done a good

job all round to the valences, wheel arches and sills along with the

boot floor and other places. Welders have a hard life and a habit of

breaking some things while they repair others - Bess's boot board will

confirm this. Anyhow, the next couple of hours were spent wiping off

the overspray of underseal and lightly brush-painting over the

boot-floor repairs.

The weekend of 17 Sep 06 has seen the rear valance and

lower edge of rear wings resprayed as well as the area around the rear

number plate. The latter has been refitted with new screws and proper

yellow plastic caps! The rear bumper and sidelights, etc., have been

refitted also and the boot floor given another light coat of paint. The

front offside rear wing has been removed and waxoyled underneath before

being fully bolted up all round. Some progress repairing Bess's broken

parcel shelf but sadly a look under the car reveals that the trusty

welder has missed a substantial bit of rust so I know the car is going

to be on its way back to him soon. It had to happen. Nevertheless, the

back end of the car is looking quite posh now.

The weekend of 1 Oct 06 has seen the nearside sill sprayed up and the front bumper refitted to the car (second time lucky; the first time I forgot the plastic trim bits that are clipped onto the front valance). The repair under the windscreen washer reservoir has had the underseal removed and has been primed up for proper painting.

The weekend of 8 Oct 06 has seen the repair under the windscreen

washer reservoir repainted and the exterior paintwork of the car has

been touched up with a fine brush. Starting to remove rust on the

battery tray, the front number plate has been replaced and the plastic

trim in the front valance refitted! Next week the plan is to start on

fitting the mudflaps and waxoyling the underside.

The weeks up to the end of 2006 have seen Blue Bess used as daily transport without major faults apart from rear indicators misbehaving sporadically. The latter was cured by cleaning the contacts on the bulbs. The steering is very light but the brakes seem a bit heavy although so far have proved to be OK. Lots of wierd noise from the exhaust was traced to loose rusty bolts which will be replaced eventually. Below the final finishing touch to the boot: a new old (and not very focussed) jack. The engine seems a tad noisier than I would like but beggars can't be...